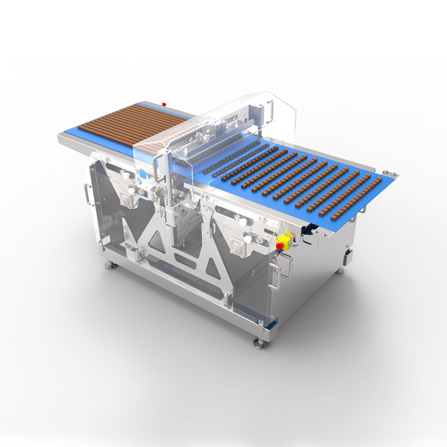

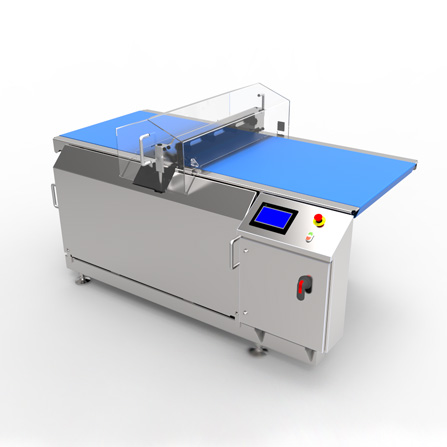

Servo Guillotine Cutting System

Product Description

Our 2-axis, Servo Controlled Guillotine system was originally developed for a customer requiring a new cutting system for their caramel production line. These products are often formed from a slab which is then slit and cut to length with production rates in excess of 500 pieces per minute. This product is also commonly used to cut cereal and granola bars to length.

Featuring two integrated, auto-tracking flat belt conveyors with dual nose bars, it is able to accurately transfer small products. The cutting bar features quick change blades coated with a special non stick coating and a pneumatic kick bar to knock products down if they stick to the blade. Encoder feedback from the belt movement combined with servo positioning accuracy ensures near perfect consistency of the product. A heavy-duty anvil and hand sharpened blade edge provides a clean cut across the full belt width (12″ to 36″ widths available).

Contact us today to see if this product is right for you.

- Touch screen PLC Control System

- Two axis servo cutting motion

- 1,000 lb cutting force

- Non-stick blade coatings

- Integrated kick bars

- Auto-tracking conveyor belts

Over 35 years of fabrication excellence.